Hubungi Kami

+86-19858305627

Email Kami

sales@maple-machinery.com

Rumah katup baja tahan karat melalui pengecoran Produsen

Pabrik kami menyediakan pengecoran pasir, penempaan mati tertutup, penempaan mati terbuka, dll. Desain ekstrim, bahan baku berkualitas, kinerja tinggi dan harga yang kompetitif adalah apa yang diinginkan setiap pelanggan, dan itu juga yang dapat kami tawarkan kepada Anda. Kami mengambil kualitas tinggi, harga yang wajar dan pelayanan yang sempurna.

Produk Panas

Bagian Pengecoran Besi Ulet Industri Daur Ulang

Mesin Maple telah beroperasi di pasar selama bertahun-tahun dan merupakan mitra terpercaya bagi kontraktor dalam dan luar negeri. Bagian Pengecoran Besi Ulet Industri Daur Ulang yang kami produksi banyak digunakan dalam Industri Daur Ulang. Kekuatan kami adalah layanan yang komprehensif - kami menyediakan produksi pengecoran khusus, serta permesinan dan perlakuan panas, sehingga sangat mengurangi waktu eksekusi pesanan. Kami memiliki toko model kami sendiri di mana kami membuat model kayu dan resin. Kami memiliki pengecoran yang lengkap dan lini produksi cetakan non-botol modern ..Katup Bagian Tempa Stainless Steel

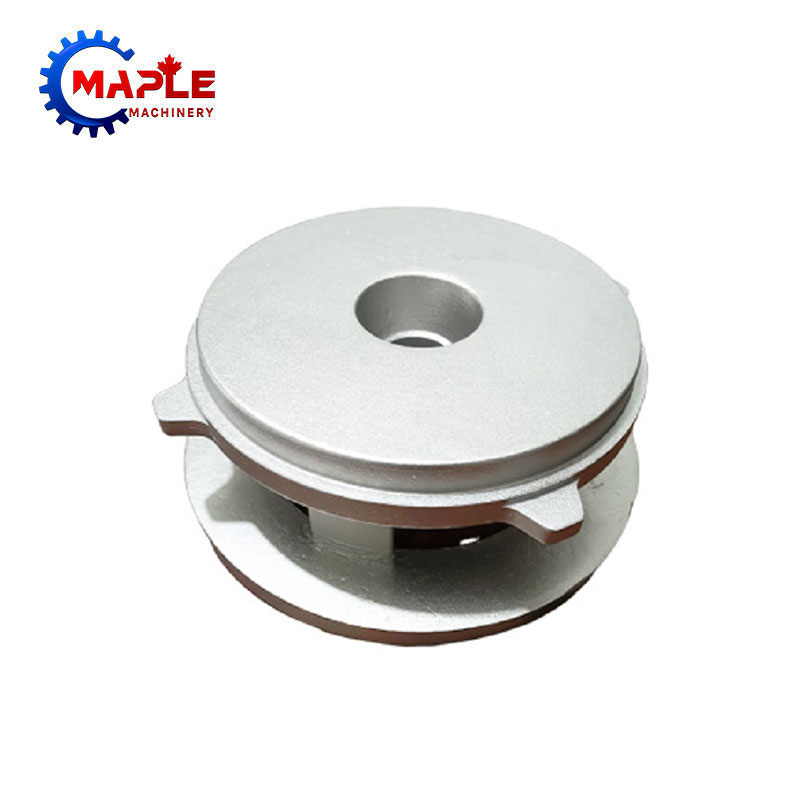

Pemrosesan Bagian Penempaan Stainless Steel Katup Kami memiliki semua teknik konvensional untuk menempa bagian. Lingkup layanan kami meliputi pemrosesan die forging stainless steel, terutama operasi penggilingan dan pembubutan pada peralatan mesin CNC. Sesuai dengan kebutuhan pelanggan, kami juga dapat menyediakan kerjasama dengan pabrik lain.Bagian Pengecoran Pasir Baja Industri Berat

Mesin Maple berspesialisasi dalam Bagian Pengecoran Pasir Baja Industri Berat berkualitas tinggi dan menyediakan pesanan produksi volume tinggi dan produksi item tunggal. Bahan utama pengecoran adalah berbagai kelas baja. Cetakan persiapan pengecoran berkualitas tinggi memungkinkan pemrosesan selanjutnya dengan margin minimal. Baja tuang menyediakan produk dengan geometri yang kompleks dan oleh karena itu seringkali merupakan satu-satunya cara untuk menghasilkan produk logam dengan struktur yang kompleks.Mesin Konstruksi Bagian Tempa Stainless Steel

Maple machinery memiliki solusi yang tepat. Gunakan layanan pemesinan CNC untuk menyederhanakan proses manufaktur. Ini membantu Anda mempercepat produksi suku cadang yang diproses secara massal dengan tingkat presisi dan presisi tertinggi. Mesin Maple dapat menyediakan Anda dengan mesin CNC online cepat, Mesin Konstruksi, Bagian Tempa Baja Tahan Karat sesuai dengan kebutuhan spesifik Anda. Kami menawarkan penawaran layanan pemesinan cepat dan suku cadang proses untuk Anda dalam waktu sesingkat mungkin.Bagian Pengecoran Investasi Baja Industri Minyak & Gas

Pengecoran Maple telah berkecimpung di industri minyak dan gas selama lebih dari 15 tahun, dan setelah kerjasama jangka panjang dengan produsen peralatan dan rantai pasokan, kami memiliki berbagai keahlian. Kami menyediakan suku cadang Pengecoran Investasi Baja Industri Minyak & Gas berkualitas tinggi, memberikan perhatian besar pada ketahanan korosi dan daya tahan suku cadang, dan kami juga secara ketat mematuhi waktu pengiriman yang diperlukan. Seperti halnya pertanian, industri ini juga memiliki potensi periodisitasnya sendiri, sehingga semua suku cadang harus dikirimkan tepat waktuMesin Konstruksi Bagian Pengecoran Besi Abu-Abu

Bagian Pengecoran Besi Kelabu adalah pengecoran logam yang umum dalam kegiatan pemrosesan logam. Prosesnya melibatkan peleburan bahan besi tuang dan mengisi cairan cair ke dalam cetakan untuk membentuk pengecoran.Besi tuang memiliki tradisi yang sangat panjang sejak 1200 SM, dan saat ini pengecoran besi tuang berkontribusi besar pada berbagai aplikasi kehidupan Mesin Konstruksi. Kita dapat melihat bahwa ada banyak produk dari Pengecoran Besi Cor dan Mesin Konstruksi Bagian Pengecoran Besi Abu-Abu.

mengirimkan permintaan

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy