Hubungi Kami

+86-19858305627

Email Kami

sales@maple-machinery.com

Pengecoran Besi Kekuatan Tinggi Produsen

Pabrik kami menyediakan pengecoran pasir, penempaan mati tertutup, penempaan mati terbuka, dll. Desain ekstrim, bahan baku berkualitas, kinerja tinggi dan harga yang kompetitif adalah apa yang diinginkan setiap pelanggan, dan itu juga yang dapat kami tawarkan kepada Anda. Kami mengambil kualitas tinggi, harga yang wajar dan pelayanan yang sempurna.

Produk Panas

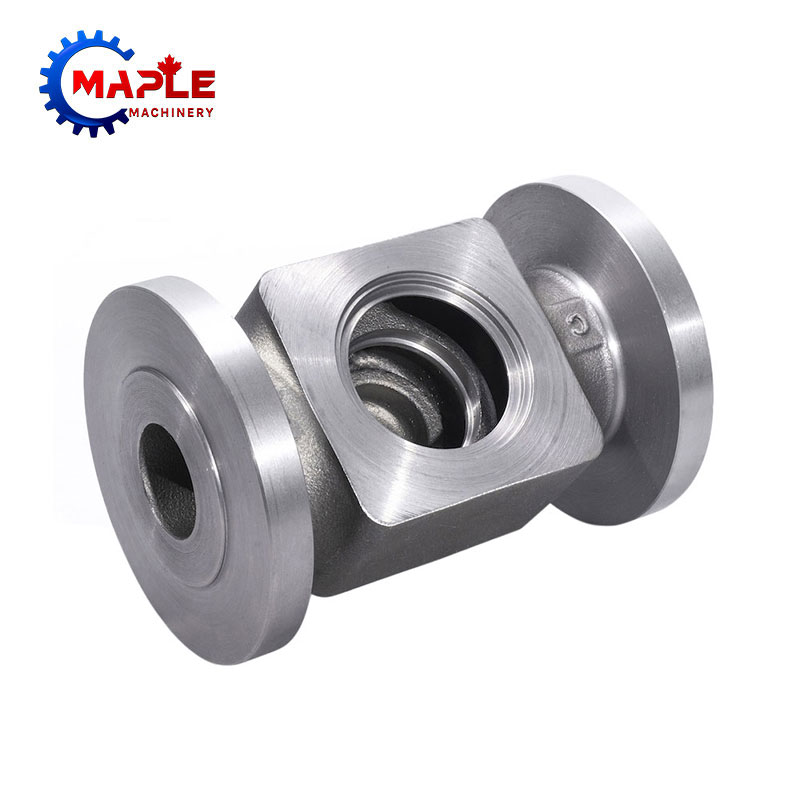

Bagian Pengecoran Lilin Hilang Baja Industri Minyak & Gas

Maple adalah perusahaan pengecoran dan pemrosesan dengan pengalaman luas, dan kami memiliki kepercayaan diri yang besar untuk melakukan yang terbaik di Industri Minyak & Gas Bagian Pengecoran Lilin Hilang Baja. Pakar Lost Wax Casting kami akan siap membantu Anda dengan semua solusi terbaik. Memenuhi kebutuhan Anda akan produk yang Anda butuhkanBagian Pengecoran Pasir Besi Mesin Pertanian

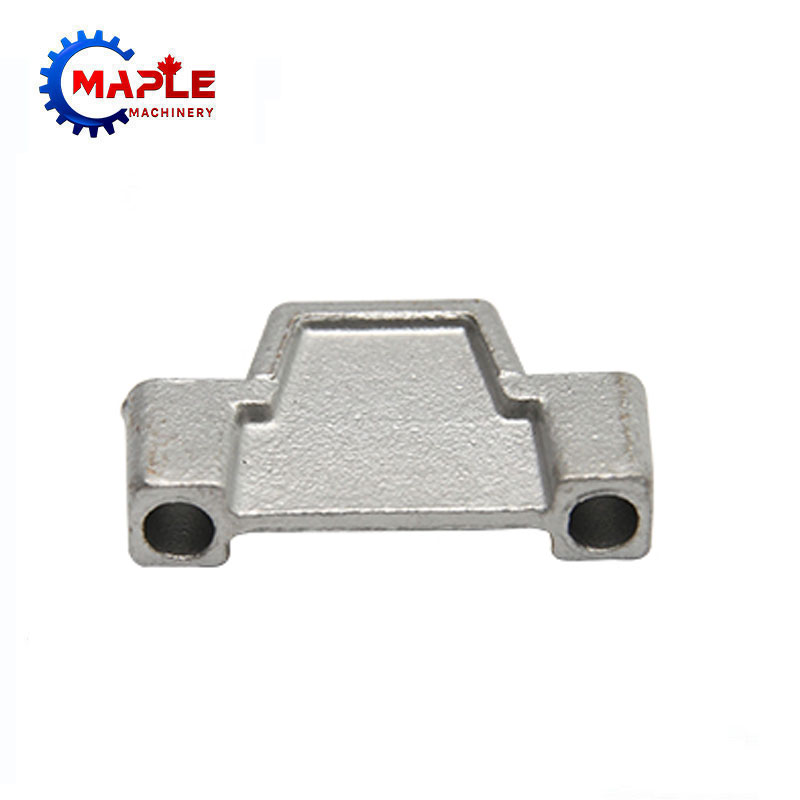

Maple Machinery memproduksi besi cor kelabu dan coran besi cor ulet sesuai dengan spesifikasi spesifik Anda, mulai dari jumlah kecil hingga besar, dan menyediakan layanan seperti perlakuan panas, pemrosesan, pengecatan, dan perakitanMaple Machinery secara langsung bekerja sama dengan produsen peralatan asli mesin pertanian untuk memproduksi Bagian Pengecoran Pasir Besi Mesin Pertanian untuk peralatan pertanian sesuai dengan spesifikasi spesifik pelanggan. Kekuatan, presisi, berat dan tampilan besi tuang yang dibuat oleh mesin Maple disukai oleh pasar mesin pertanian. Pelanggan kami di industri mesin pertanian memproduksi Mesin Pertanian Bagian Pengecoran Pasir Besi untuk traktor, pemanen gabungan, gerbong, pekebun, penyebar, bajak , peralatan pertanian dan mesin pertanian lainnya.Baja Industri Berat Bagian Penempaan Mati Tertutup

Mesin Maple berspesialisasi dalam Penempaan Mati Tertutup, membuat Bagian Penempaan Mati Tertutup Baja Industri Berat berkualitas tinggi. Ruang lingkup bisnis kami adalah pemasaran global. Saat ini, perusahaan telah menjalin hubungan kerja sama jangka panjang dengan banyak pelanggan terkenal di dalam dan luar negeri. Budaya mesin Maple adalah menciptakan nilai untuk eksploitasi diri. Penerima manfaat terbesarnya adalah pelanggannya. Hasilnya, mesin Maple telah dan akan terus menjadi mitra yang andal dan berdedikasi bagi pelanggan kami.Mesin Pengolah Makanan Bagian Pengecoran Pasir Besi

Cast berkualitas tinggi, suku cadang mesin dengan harga bersaing dari pemasok terpercaya. Maple Machinery adalah produsen komponen logam terkenal di China dan pemasok Mesin Pengolah Makanan yang andal. Mesin Pengolah Makanan membutuhkan Bagian Pengecoran Pasir Besi Mesin Pengolah Makanan dengan presisi tinggi. Kami dapat melakukan pekerjaan dengan baik pemasok produk utama dari semua komponen sistem penting.Bagian Pengecoran Pasir Baja Mesin Konstruksi

Keahlian kami di berbagai bidang banyak digunakan. Kami telah mendiversifikasi teknologi produksi dalam Mesin Konstruksi, dan menyediakan Bagian Pengecoran Pasir Baja Mesin Konstruksi berkualitas dan layanan untuk pelanggan Mesin Konstruksi. Untuk menyediakan pelanggan dengan produk dan layanan berkualitas, untuk menyediakan pelanggan dengan produk dan layanan berkualitas.Badan Katup Pengecoran Pasir Besi Ulet

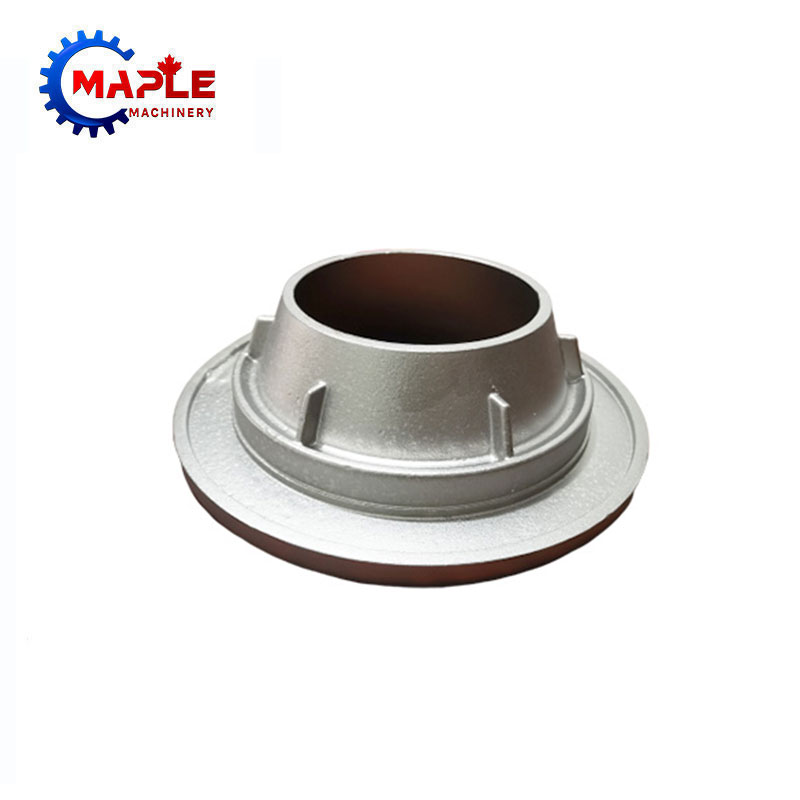

Maple Machinery adalah penyedia terkemuka solusi Badan Katup Pengecoran Pasir Besi Ulet yang disesuaikan. Tim kami yang sangat terampil membawa pengetahuan teknis dan pengalaman yang luas untuk mengembangkan solusi khusus yang dirancang untuk memenuhi kebutuhan unik pelanggan kami. Kami memegang teguh standar kerahasiaan, akuntabilitas, dan keberlanjutan tertinggi dalam hubungan kami dengan semua pihak yang berkepentingan, dengan mempertimbangkan tujuan jangka menengah dan panjang Valve.

mengirimkan permintaan

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy