Hubungi Kami

+86-19858305627

Email Kami

sales@maple-machinery.com

Bagian Pengecoran Besi Presisi Produsen

Pabrik kami menyediakan pengecoran pasir, penempaan mati tertutup, penempaan mati terbuka, dll. Desain ekstrim, bahan baku berkualitas, kinerja tinggi dan harga yang kompetitif adalah apa yang diinginkan setiap pelanggan, dan itu juga yang dapat kami tawarkan kepada Anda. Kami mengambil kualitas tinggi, harga yang wajar dan pelayanan yang sempurna.

Produk Panas

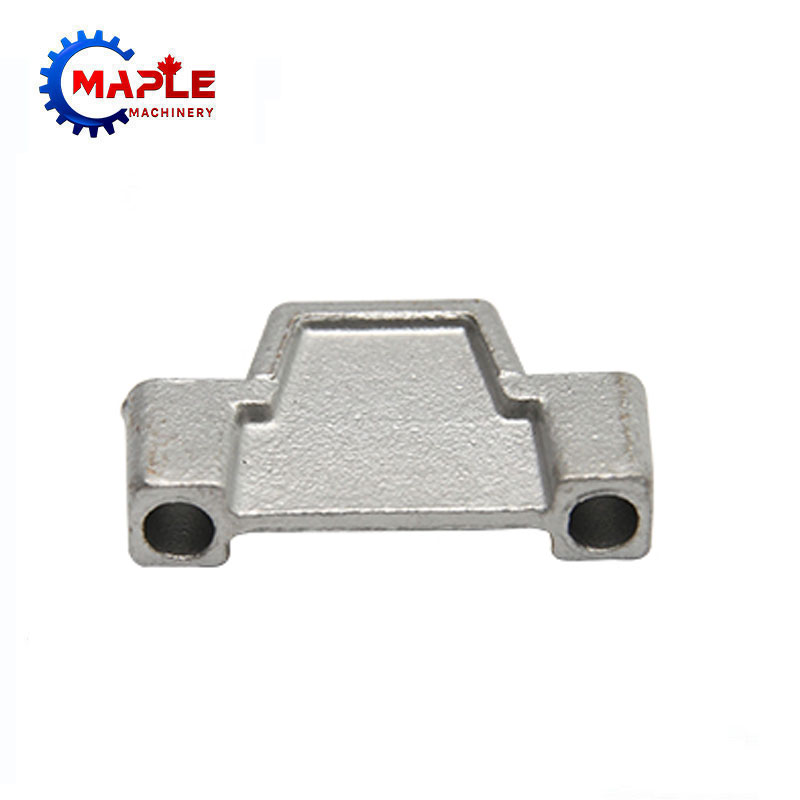

Bagian Pengecoran Besi Ulet Mesin Pertanian

Pemasok produk Besi Ulet selama lebih dari 15 tahun Mesin Maple adalah produsen profesional Bagian Pengecoran Besi Ulet Mesin Pertanian, juga untuk pertambangan, penggalian, Pembangkit listrik dan industri teknik umum menghasilkan berbagai macam paduan dan besi yang sangat tahan aus dan pengecoran besi baja. Pabrikan bersertifikasi ISO 90001 kualitas, menyediakan coran kualitas tertinggi untuk produsen pertanian dunia dan pemasok peralatan pertanian terkemuka dunia..Bagian Pengecoran Lilin Hilang Baja Teknik Sipil

Untuk mencapai kepuasan maksimal dari pelanggan kami yang terhormat, kami berkomitmen untuk menyediakan Bagian Pengecoran Lilin Hilang Baja Teknik Sipil kelas satu. Desain yang tepat dan pengembangan yang kuat, untuk perusahaan baja, material, dan kebutuhan sehari-hari untuk memberikan pilihan produksi yang sesuai. Produk-produk ini menggunakan teknologi inovatif terbaru dan diproduksi secara ketat sesuai dengan standar industri. Selain itu, ini dapat dimodifikasi untuk memenuhi prasyarat khusus pelanggan.Off Highway Industry Steel Kehilangan Bagian Pengecoran Lilin

Maple machinery has a number of casting plants, with strong processing capacity Specializing in the production of carbon steel, alloy steel, stainless steel, high temperature alloy and other wax lost casting parts and machining parts. Maple's superior quality of Off Highway Industry Steel Lost Wax Casting Parts attracts equally excellent customers, enabling our products to serve various machinery industries. 产品内容 Off Highway Industry Steel Lost Wax Casting Parts Product Introduction Off Highway Industry Steel Lost Wax Casting Parts is a product that Maple machinery has been doing. Lost wax casting is now called investment casting. It is a precision casting process with little or no cutting. It is not only suitable for precision casting of various types and alloys, but also produces castings with higher dimensional accuracy and surface quality than other precision casting methods. In order to meet the needs of different customers, we use two kinds of wax, namely yellow low temperature wax and green medium temperature wax. 2. Product Parameter (Specification) Item Off Highway Industry Steel Lost Wax Casting Parts Roughness Ra 1.6 Tolerance ±0.01mm Material Casting Steel/Casting Iron Certification ISO 9001:2015 Weight 0.01-5000KG Machining CNC Heat Treatment Quenching & Tempering Inspection MT/UT/X-Ray Lead Time 30 Days Package Plywood Case Method Sand Casting Capacity 50000 Pcs / Month Origin Ningbo, China 3. Maple’s Services for Off Highway Industry Maple machinery has been increasing its manufacturing capacity for Off Highway Industry Steel Lost Wax Casting Parts for many years. Provide high quality Off Highway Industry Steel Lost Wax Casting Parts for our machining operations to meet and satisfy customer needs. We are able to process different types of castings, including: pressure die casting and sand castings. We assist our customers to select the most appropriate casting type according to the required volume and complexity, providing the most cost effective solution. The railway sector provides a crucial network for transport and distribution. It needs cost-effective and long-lasting equipment that is dependable for the range of applications. The railways, from freight to passenger, need different castings for various applications. Maple Machinery carries extensive experience to create steel castings and iron castings in varying sizes, shapes, and materials that are precise, strong, and durable. We manufacture a wide range of castings and forgings for railway infrastructure and transportation equipment. 4.Supporting Service for Off Highway Industry parts As mentioned above, in order to work in adverse conditions, the performance of the Off Highway Industry Steel Lost Wax Casting Parts must be excellent. Therefore, it’s not enough to only produce raw castings or forgings, but also need heat treatment, machining, surface treatment, NDT testing, etc. Heat treatment: heat treatment is the critical step to improve the mechanical properties of the workpiece. We can formulate the process according to the strength requirements of the parts, and improve the mechanical properties of the parts such as hardness, yield strength, tensile strength and elongation by heat treatment Machining: we have our own machine shop, and can complete almost all machining requirements with advanced equipment. Surface treatment: the purpose of surface treatment is to make parts work in adverse environment. Zinc plating can prevent parts from rusting; Nickel plating can enhance the wear resistance and corrosion resistance of parts; Phosphating can prevent parts from corrosion… Non-destructive testing (NDT): NDT is the last and most important step. Maple will NDT the parts to ensure that there are no surface defects (such as cracks, sand holes, blow holes) and no internal defects (shrinkage and slag) on the delivered parts. Common Material for Off Highway Industry parts We have the ability to manufacture all steel standard materials as well as special materials. The following are our common materials for manufacturing Off Highway Industry Steel Lost Wax Casting Parts: Carbon Steel:1015, 1020, 1035, 1045, 20Mn, 25Mn, A570.GrA, SJ355, C45… Alloy Steel:4130, 4135, 4140, 4340, 8620, 8640, 20CrMo, 42CrMo4, 34CrNiMo6, 25CrMo… Stainless steel:304, 304L, 316, 316L, 410, 416, CF8, CF8M, PH17-4, CK20… Gray Iron:GG-15, GG-20, GG-25, Class 20B, Class 25B, Class 30B, GJL-250, GJL-300… Ductile Iron:GGG-40, GGG-50, 60-40-18, 65-45-12, 70-50-05, 80-55-06 QT500-7, QT400-18, QT700-2 … High Chromium cast iron:15%Cr-Mo-HC, 20%Cr-Mo-LC, 25%Cr… Aluminum:AlSi7Mg, AlSi12, AlSi10Mg, A356, A360… High Manganese steel: X120Mn12, Mn12, Mn13… 5.The Parts We Supplying for the Off Highway Industry We have manufactured a wide range of Off Highway Industry Steel Lost Wax Casting Parts. The following are typical products: Coupling components, Centre plates, Bearing brackets, Rail wheels, Wheel hub, Base plate, Axle boxes, Yokes, Pedestals, Hinges, Tie plates, Side jaw clip, and Joint bar. 6. Why Sand Casting Sand casting is an ancient casting process where the metal parts are molded by pouring metal into a hollow cavity. The mold-based manufacturing process is used to make castings with materials of iron, steel, and Aluminum. Casting-based manufacturing includes several steps and can create a wide range of shapes and sizes for metal products. The process begins with the making of a mold pattern and a gate system with the exact size and shape of the required part. The temperature required depends on the metal as some metals take a long time to heat and melt. Maple Machinery has continuously upgraded its Sand-casting equipment and refined the casting process. The aim behind this is to use only the advanced casting technology for its Sand-casting operations. Each step follows the customer’s drawings and instructions to deliver precise solutions.Bagian Pengecoran Pasir Baja Industri Jalan Raya

Mesin Maple memiliki sejarah panjang dan membanggakan Pengecoran Pasir Baja di Cina, menetapkan tolok ukur untuk Bagian Pengecoran Pasir Baja Industri Off Highway. Sejak didirikan, mesin Maple telah berfokus pada penjualan Suku Cadang Pengecoran Pasir Baja untuk Industri Off Highway. Dengan lebih dari 15 tahun pengalaman pengecoran dan jaringan manufaktur dan distribusi yang luas, kami berada di garis depan industri dalam hal kualitas produk, inovasi, dukungan teknis, dan layanan pelanggan.Bagian Penempaan Stainless Steel Industri Berat

Kami adalah pemasok terkemuka produk tempa di China dengan sejarah hampir 20 tahun. Kami berspesialisasi dalam Bagian Penempaan die tertutup yang terbuat dari paduan, paduan mikro, karbon, dan Baja konstruksi, termasuk Bagian Penempaan Baja Tahan Karat Industri Berat. Strategi kami didasarkan pada kemitraan dengan perusahaan terkemuka Amerika Utara dan global yang telah menjalin kemitraan yang stabil dan jangka panjang dengan kami.Bagian Pengecoran Investasi Baja Sistem Hidrolik

Maple adalah pemain kunci dalam industri proses di bidang pengecoran investasi presisi. Maple telah mengembangkan banyak Bagian Pengecoran Investasi Baja Sistem Hidrolik, yang biasanya dicetak menjadi paduan khusus. Paduan khusus ini digunakan karena komponen biasanya bekerja di lingkungan yang korosif (keras), memiliki perbedaan suhu yang besar, atau membutuhkan produk yang sangat keras, kuat, atau ringan.

mengirimkan permintaan

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy