Hubungi Kami

+86-19858305627

Email Kami

sales@maple-machinery.com

Pengecoran Stainless Steel untuk Pengolahan Makanan Produsen

Pabrik kami menyediakan pengecoran pasir, penempaan mati tertutup, penempaan mati terbuka, dll. Desain ekstrim, bahan baku berkualitas, kinerja tinggi dan harga yang kompetitif adalah apa yang diinginkan setiap pelanggan, dan itu juga yang dapat kami tawarkan kepada Anda. Kami mengambil kualitas tinggi, harga yang wajar dan pelayanan yang sempurna.

Produk Panas

Industri Pertambangan Baja Bagian Pengecoran Lilin yang Hilang

Industri Pertambangan Steel Lost Wax Casting Parts kami banyak digunakan di bidang pertambangan dan pengolahan mineral. Dengan kualitas tinggi dan stabil, kami memiliki lebih dari 20 tahun pengalaman profesional. Kami memiliki teknologi pengecoran canggih, yang dapat memenuhi persyaratan teknis tahan ledakan dari pelanggan mesin pertambangan. Jika Anda perlu memberi Anda solusi dari aspek desain, simulasi, pengecoran dan permesinan, dan memberikan beberapa saran efektif untuk penerapan Bagian Pengecoran Lilin Hilang Baja Industri Pertambangan Anda, kami dengan senang hati menjadi ahli pengecoran Anda.Bagian Penempaan Baja Industri Pertambangan

Maple Machinery adalah ahli manufaktur satu atap berdasarkan casting dan permesinan, penempaan dan casting terkait erat. Oleh karena itu, mesin maple telah menyediakan Suku Cadang Penempaan Baja Industri Pertambangan profesional untuk pelanggan selama lebih dari sepuluh tahun sejak didirikan. Kami tidak memiliki peralatan penempaan di pabrik kami, tetapi ada tiga pabrik penempaan dengan teknologi yang sangat baik di Ningbo telah menjalin hubungan kerjasama dengan kami selama lebih dari sepuluh tahun. Mereka tidak memiliki departemen perdagangan internasional, tetapi kapasitas penempaan mereka luar biasa di lokal. Mereka memiliki peralatan penempaan yang canggih. Mesin pres gesekan 300t, 400t, 600t, 1200t dan 1600t dapat menghasilkan tempa sekecil puluhan gram dan sebesar 60kg.Mesin Pertanian Baja Tertutup Die Forging Parts

MapleMachinery memiliki hampir 20 tahun pengalaman layanan di industri peralatan pertanian. Kami menempa dan memproses paduan, termasuk baja karbon, baja paduan, baja tahan karat, dan aluminium. Penggunaan akhir tempa kami berkisar dari bagian mesin pertanian hingga komponen utama peralatan panen tanaman. Untuk mengurangi biaya peralatan pertanian, maple telah mengotomatiskan beberapa proses penempaan, yang dapat memproduksi Bagian Penempaan Baja Mesin Pertanian Bersih Tertutup dengan sifat mekanik yang konsisten, dan sangat mempersingkat siklus produksi.Bagian Pengecoran Pasir Besi Industri Berat

Mesin Maple, berlokasi di Ningbo, Cina, adalah pabrik pengecoran yang memproduksi berbagai macam Bagian Pengecoran Pasir Besi Industri Berat untuk aplikasi Industri Berat. Kami juga memproduksi komponen mesin performa tinggi, termasuk ring piston mesin diesel, liner silinder, dan batang penghubung. Kami bangga untuk mengatakan bahwa kami telah mendapatkan reputasi sebagai pemasok beberapa Pengecoran Pasir Besi dengan kualitas terbaik di dunia. Karena kualitas dan komitmen pelanggan kami diwujudkan untuk pelanggan.Mesin Pengolah Makanan Bagian Pengecoran Besi Abu-Abu

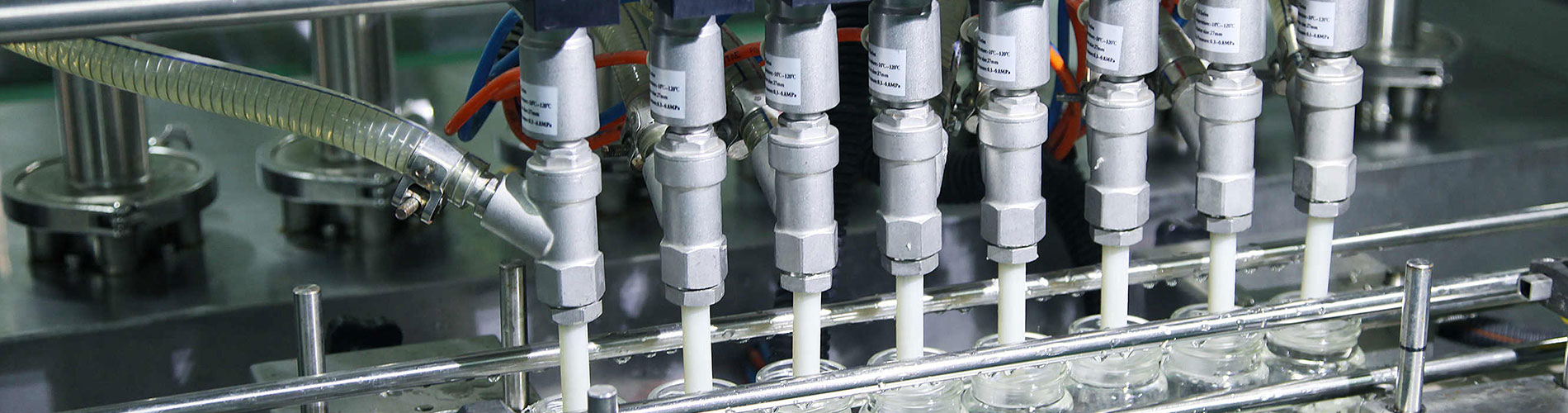

Mesin Proses Makanan Perusahaan kami Bagian Pengecoran Besi Abu-abu menikmati reputasi tinggi di antara pengguna akhir yang memproduksi berbagai peralatan Mesin dan mesin pemotong logam. Berbagai macam coran digunakan pada mesin Proses Makanan umum. Kami juga menyediakan peralatan die core, Peralatan ini sesuai dengan teknologi pengecoran logam kami sendiri, yang menjamin kualitas tinggi permukaan dalam dan luar coran..Bagian Pengecoran Besi Ulet Mesin Pertanian

Pemasok produk Besi Ulet selama lebih dari 15 tahun Mesin Maple adalah produsen profesional Bagian Pengecoran Besi Ulet Mesin Pertanian, juga untuk pertambangan, penggalian, Pembangkit listrik dan industri teknik umum menghasilkan berbagai macam paduan dan besi yang sangat tahan aus dan pengecoran besi baja. Pabrikan bersertifikasi ISO 90001 kualitas, menyediakan coran kualitas tertinggi untuk produsen pertanian dunia dan pemasok peralatan pertanian terkemuka dunia..

mengirimkan permintaan

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy