Hubungi Kami

+86-19858305627

Email Kami

sales@maple-machinery.com

Bagian pengecoran investasi peralatan pemindahan tanah Produsen

Pabrik kami menyediakan pengecoran pasir, penempaan mati tertutup, penempaan mati terbuka, dll. Desain ekstrim, bahan baku berkualitas, kinerja tinggi dan harga yang kompetitif adalah apa yang diinginkan setiap pelanggan, dan itu juga yang dapat kami tawarkan kepada Anda. Kami mengambil kualitas tinggi, harga yang wajar dan pelayanan yang sempurna.

Produk Panas

Bagian Pengecoran Investasi Baja Industri Daur Ulang

Mesin Maple terletak di Ningbo, kota yang dekat dengan pelabuhan, yang sangat bermanfaat untuk pekerjaan transportasi kita. Ini kondusif untuk pertukaran produk kami. Perkembangan Bagian Pengecoran Investasi Baja Industri Daur Ulang menunjukkan tren peningkatan di dunia. mesin maple telah terlibat dalam penelitian yang sedang berlangsung ke dalam Bagian Pengecoran Investasi Baja Industri Daur Ulang.Bagian Pengecoran Presisi Baja Industri Jalan Raya

Mesin Maple adalah perusahaan baja cor profesional, penghasil dan pengekspor suku cadang baja cor berkualitas tinggi, dengan lebih dari 15 tahun pengalaman dalam ekspor. Kami menggunakan peralatan pendeteksi produksi jebakan untuk memproduksi Bagian Pengecoran Presisi Baja Industri Jalan Raya Off. Manajemen pesanan satu ke satu, berkomunikasi tepat waktu dengan pelanggan tentang situasi produk.Bagian Pengecoran Investasi Baja Katup

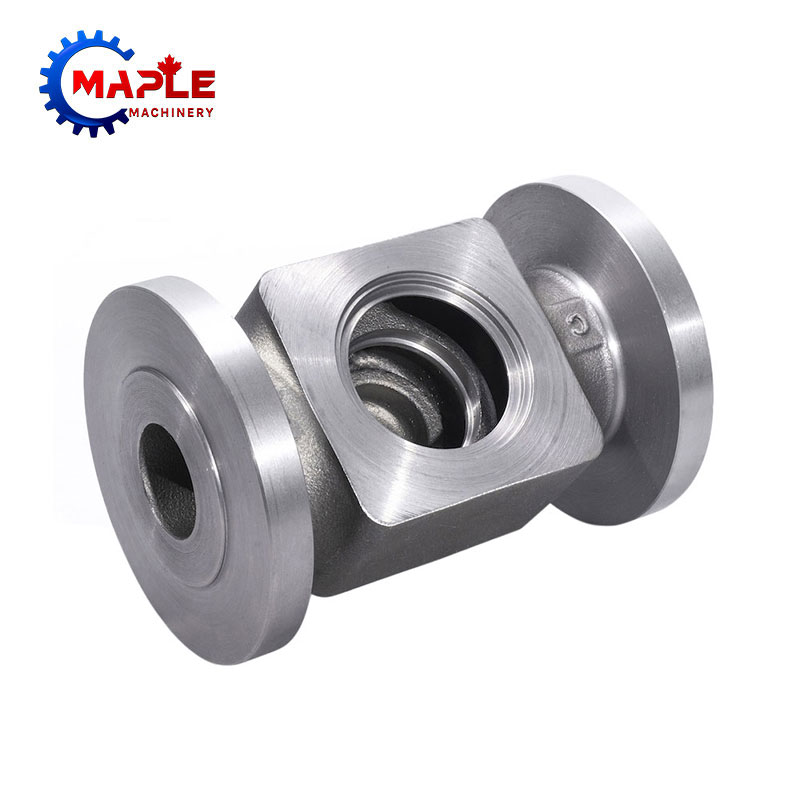

Dalam mesin maple, kami memiliki pengalaman Pengecoran yang luas untuk Bagian Pengecoran Investasi Baja Katup, memungkinkan pelanggan kami mendapatkan pengecoran berkualitas tinggi dari proses pengecoran investasi dengan biaya ekonomis. Kami memiliki tim teknis yang sangat baik dengan pengalaman bertahun-tahun untuk memberi Anda desain pengecoran investasi terbaik. Bantuan apa pun yang diperlukan - mulai dari tinjauan toleransi sederhana hingga rekayasa serentak penuh - tersedia di lokasi pengecoran kami. Bagian Pengecoran Investasi Baja Katup, mesin maple dapat memberi Anda yang terbaik.Bagian Pengecoran Investasi Baja Teknik Sipil

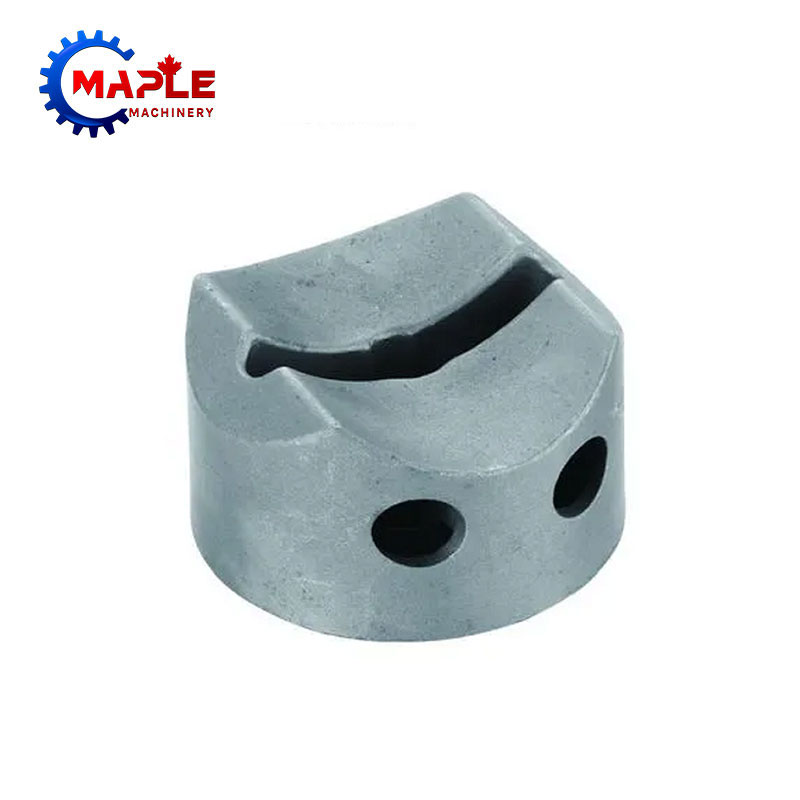

Maple Machinery telah mengumpulkan banyak pengalaman pengecoran di Bagian Pengecoran Investasi Baja Teknik Sipil selama bertahun-tahun dalam kombinasi dengan kebutuhan pengembangan industri konstruksi saat ini. Sementara itu, dengan perkembangan sosial ekonomi yang berkelanjutan, sifat struktural Bagian Pengecoran Investasi Baja Teknik Sipil terus meningkat, dan teknologi kami juga meningkat.Bagian Pengecoran Besi Ulet Industri Off Highway

Jika Anda memilih mesin Maple, Anda memilih produsen Suku Cadang Pengecoran Besi Ulet berpengalaman yang sangat menyukai profesinya. Mesin Maple memiliki hampir 20 tahun pengalaman dalam pengembangan dan produksi Bagian Pengecoran Besi Ulet Industri Off Highway. Setiap langkah Pengecoran Besi Ulet menyadari bahwa hasrat dan kualitas berjalan seiring. Dengan cara ini, setiap orang berkembang setiap hari sebagai tim sekuat besi.Bagian Pengecoran Baja Industri Berat

Mesin Maple memiliki lebih dari lima belas tahun pengalaman memproduksi Bagian Pengecoran Baja Industri Berat. Kami akan melakukan pemeriksaan langsung pada setiap proses dan melakukan pemeriksaan perantara 100%. Dan komunikasi dan komunikasi pelanggan harus tepat waktu dan akurat. Produk yang dibuat khusus untuk pelanggan, kami harus menjadi yang paling profesional. Di antara produk Casting mesin Maple, kami memproduksi coran investasi presisi dengan berbagai Bagian Pengecoran Baja Industri Berat. Coran investasi baja, baja tahan karat, dan aluminium kami banyak digunakan di pasar perangkat keras. Proses pengecoran investasi adalah pilihan yang sangat baik untuk menghasilkan produk perangkat keras dengan dimensi yang akurat. Sejumlah besar suku cadang ukuran presisi di Industri Berat.2. Parameter Produk (Spesifikasi)

mengirimkan permintaan

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy